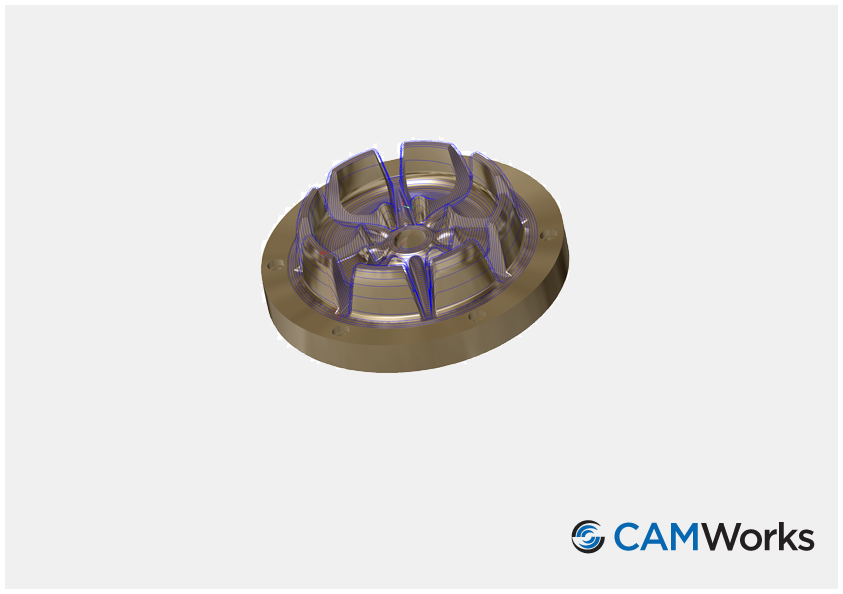

3 Axis Milling

- Feature-based machining - Reduces programming time by as much as 90% compared to other traditional 3 axis CAM software.

- Knowledge-based machining - Allows you to capture and reuse the best practices for various operations

- Full toolpath associativity to solid models - Automatically updates the tools paths and CAM data

- CAMWorks VoluMill™ - the ultra-high performance toolpath generator for rough milling operations

While CAMWorks 3 Axis cycles are developed for speed, accuracy and efficient memory usage, it also ensures that simple and complex parts can be cut quickly and accurately with a high-quality toolpath.

- Adaptive roughing strategy provides the ability to cut using the full depth of the tool and safely run your machine at optimum speed. This can reduce machining time up to 40% over conventional roughing with less wear.

- 3 Axis finishing operations include parallel slice cut, constant stepover, Z-level, curve project, and others

- Z Level/Constant stopover combination operation can be used for machining steep and shallower slope areas in one toolpath.

- All 3 Axis milling operations support rest or leftover machining. Rest machining is used to reduce air cutting by restricting toolpaths to areas within the feature that have not been machined previously.

- The curve project cycle removes material by projecting 2.5 Axis engrave or curve features on the 3 Axis feature. CAMWorks can calculate a single pass or multiple passes for engraving.

- Provide the ability to generate toolpaths as separate threads and in separate processes. Multiple toolpaths will generate simultaneously and at the same time the user can continue working in other areas or on other CAM models.