Turning

CAMWorks 2 and 4 Axis Turning software for programming CNC lathe machines includes automatic roughing, finishing, grooving, threading, cutoff and single point (drilling, boring, reaming and tapping) cycles. CAMWorks, incorporates Machining Intelligence for Automation, a suite of tools that automate Feature Recognition and the generation of toolpaths based on a user-defined technology database.

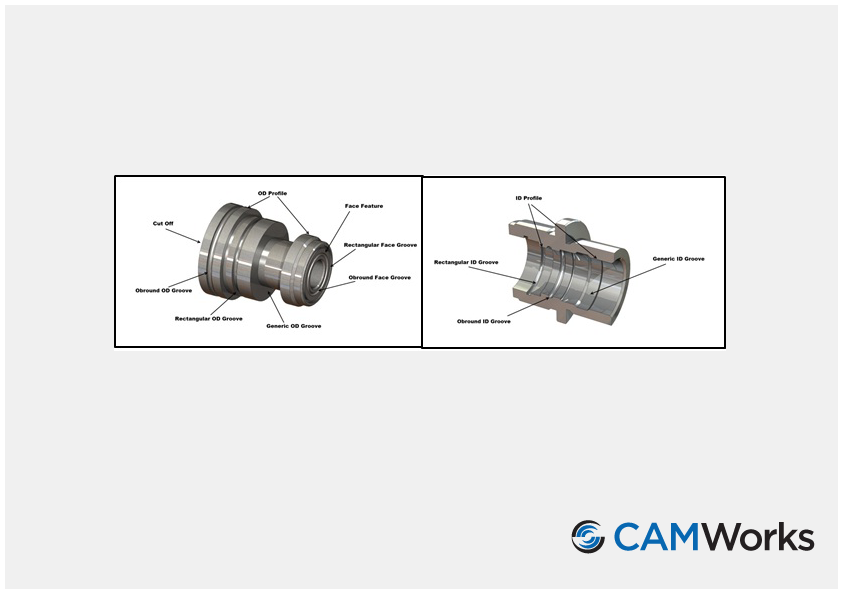

Automatic and Interactive Feature Recognition

Automatic Feature Recognition (AFR) analyzes the part shape and defines the most common machinable features such as the OD and ID of the part, front face and grooves.

- AFR recognizes features on native solid models or on solid parts imported via IGES, SAT, etc.

- When bar stock is used, AFR generates a cutoff feature on the opposite side of the face feature.

- CAMWorks provides an Interactive Turn Feature wizard for defining features that need to be defined for your facility’s machining requirements, such as custom OD and ID grooves.

Turning for 2 and 4 Axis Lathes

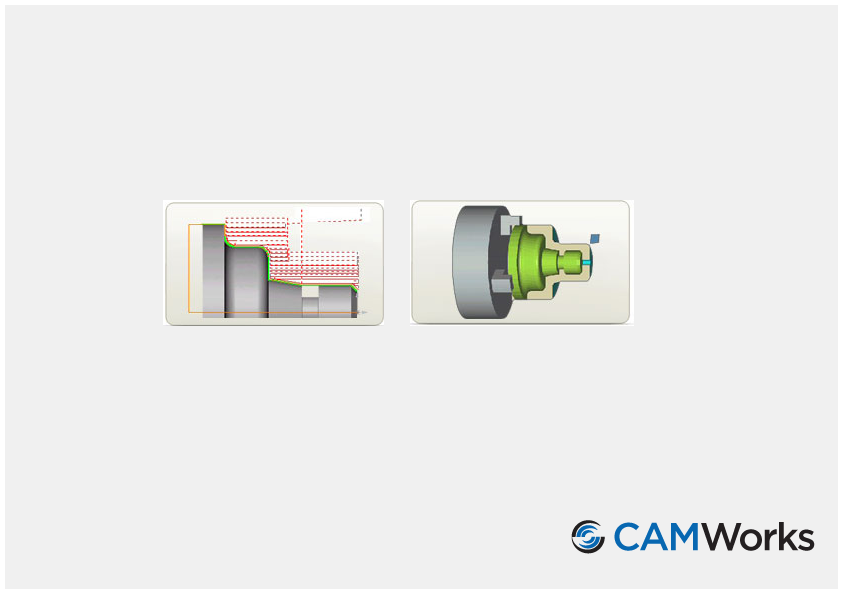

CAMWorks Turning provides fast, error-free cutting using standard inserts for both front and rear turret configurations and toolpath, simulation and post processing support for sub-spindles.

- Machining algorithms use the latest toolpath and gouge protection methods

- Define stock as bar stock, a revolved sketch, a 2D WIP sketch or from an STL file.

- Work in process (WIP) monitoring of stock increases cutting efficiency.

- Define chuck to use for toolpath simulation.

- Simulated stock shape can be saved as an STL file for use as Turn, Mill-Turn, Mill or Wire EDM stock shapes.

- Toolpath, simulation and post processing support for sub-spindles.

- Extend or shorten the length of a turn feature from within face rough/finish, turn rough/finish, bore rough/finish and cutoff operations.

- Reverse machining for face finish, turn finish, bore rough and bore finish.

- Reverse machining for threading to generate left hand threads.

- Output for turning canned/fixed cycles for drilling, rough OD/ID turning and facing operations.

- Drill and center drill tools for both mill and turn can be specified from a common drill and center drill database.

- Option to associate new turn features to current turn features. CAMWorks generates new operations for the new feature that are copies of the operations for the selected current feature.

- Cutoff operation spindle speed/feedrate slowdown option to decrease the speed and feedrate at a user specified length from the end of a cutoff toolpath.

- Rough groove cleanup pass to remove scallops generated by the rough groove toolpath.

- Finish groove cutter compensation support.

- Single pass option for groove cycle.

- Multiple groove tool driving point options.

- Option to set minimum and maximum Z limits for turn operations either globally or for each operation.

- Back turning support.

- Option to define varying allowances on turn toolpaths.

- Ability to mirror about the centerline to generate toolpaths below centerline.

- APT CL support for external post processing.

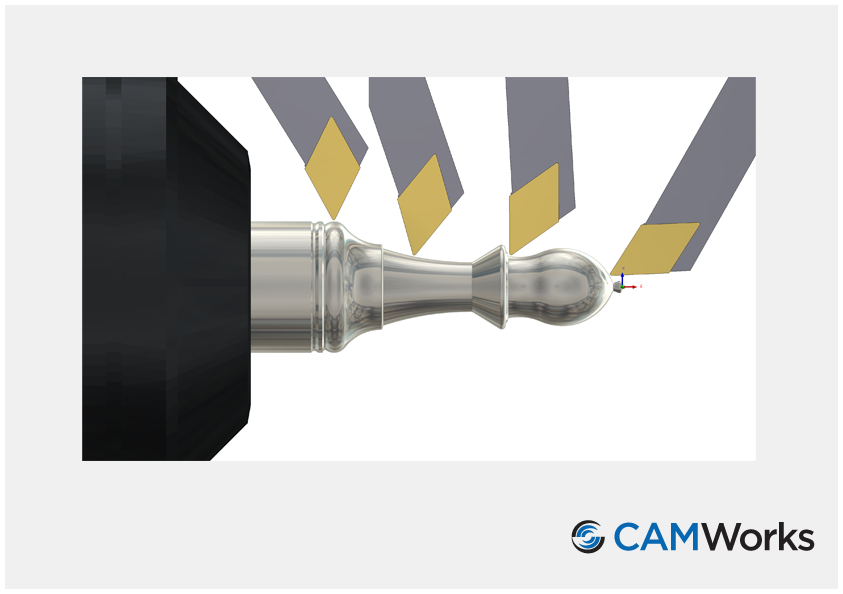

The use of a machine with the continuous B axis capability is best suited for complex geometry parts. Complex parts can be machined in one setup by using the B axis cutting capability, which helps avoid the need to reconfigure the tool. The ability to manipulate the tool to any angle in very precise increments is a primary benefit of having a B axis. Using traditional methods, this can be a slow and tedious process, but CAMWorks makes it simple.

In CAMWorks there are two methods to control angles, with an option to control angle increments and angle limits. CAMWorks alco makes it easy to control arcs and transition of the tool along external and internal corners.

In CAMWorks there are two methods to control angles, with an option to control angle increments and angle limits. CAMWorks alco makes it easy to control arcs and transition of the tool along external and internal corners.