Vision-Based Inspection Systems Deployment

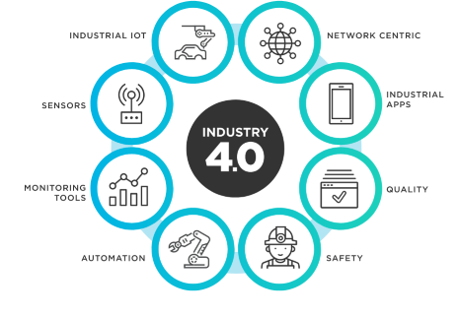

Industrial IoT & Industry 4.0 Integration

Automated Test Equipment (ATE) Systems Design

Hardware-in-the-Loop (HIL) Testing Development

Industrial Automation & Control Systems

Embedded Systems & Firmware Development

Automotive & Embedded Services

Automotive & Embedded Systems

- Hardware-in-the-Loop (HIL) testing for automotive ECUs

- Automated Test Equipment (ATE) systems for end-of-line (EOL) testing

- Custom tool development for ECU simulations and flashing

- Cybersecurity testing for automotive ECUs

- HMI testing for infotainment and instrument cluster ECUs

LabVIEW & TestStand Consulting

- Expert consulting for test automation using LabVIEW and TestStand

- Integration of automated workflows to improve design and testing efficiency

- Custom automation frameworks for complex automotive testing requirements

Industrial IoT & Connected Factory 4.0

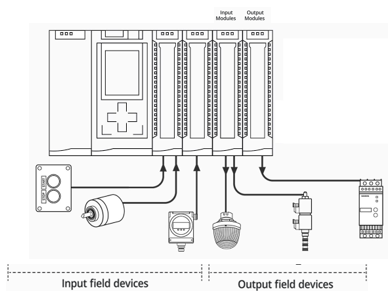

- System automation using PLC, PXI, and cRIO platforms

- Vision-based inspection systems for smart manufacturing

- Seamless integration with IIoT for real-time monitoring and control

Hardware & Automation Testing

- End-to-end hardware test automation solutions

- Automation systems using PLCs for enhanced efficiency

- End-of-line ECU testing for automotive production

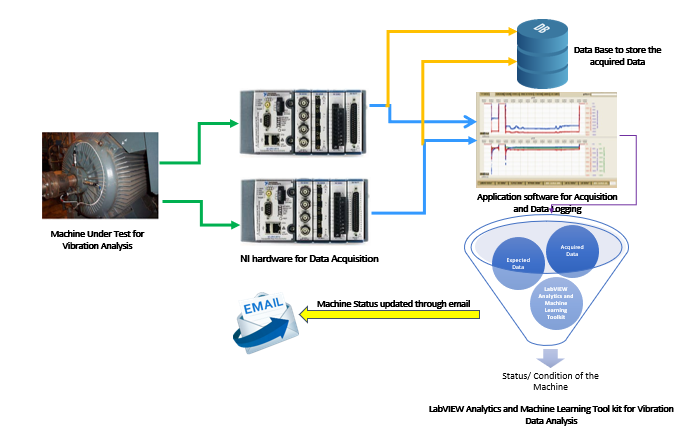

- Structural health monitoring test systems

- Complete system integration for reliable performance

Data Logging Systems

Our advanced data logging systems provide comprehensive monitoring of automotive and embedded processes. They capture real-time signals, ensuring accurate testing and analysis, enabling engineers to optimize performance, detect anomalies early, and maintain reliability across diverse applications in embedded services.

System Architecture & Design

We create robust system architecture solutions for embedded systems and automation. These designs integrate hardware and software efficiently, supporting seamless testing, high performance, and maintainable solutions for automotive, industrial, and IoT applications, tailored to complex engineering requirements.

Approach

- Use of NI LabVIEW: Develops a sophisticated software architecture for testing, leveraging both off-the-shelf and custom hardware.

- Scalable and Intuitive Testing: Provides efficient and intuitive testing on a singular, tightly controlled platform.

Solution

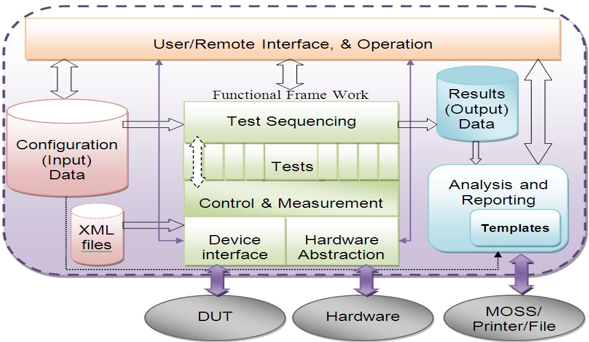

Layered Functional Framework: Four-layer architecture designed to meet key software requirements.

- Perform large numbers of similar and disparate tests.

- Test multiple devices in sequence or in parallel.

- Support concurrent development of test and measurement hardware.

- Minimize software changes when tests or hardware are updated.

- Highly maintainable and scalable due to discrete layer definitions.

Functional Framework Layers

- Test Sequencing: Executes parameterized tests and collects results.

- Tests: Library of customizable tests; interacts with the Control & Measurement (CAM) layer.

- Control & Measurement (CAM): Library of single operations used to execute tests.

- Hardware Abstraction Layer (HAL): Translates CAM operations to physical hardware actions.

Build Versus VI

- Dynamic Built Application: Primary software delivered as built application.

- Independent LabVIEW Code: Test and hardware driver libraries remain as VIs for easy future expansion.

- Minimal LabVIEW Knowledge Required: Test engineers can implement additional tests without modifying the core framework.

Hardware Abstraction Layer (HAL)

- Isolation of Higher Layers: HAL shields the framework from hardware specifics.

- Supports Legacy and New Hardware: Drivers downloaded from LabVIEW Instrument Driver Network.

- Automatic DUT Adaptation: Special HAL cases handle automatic communication adjustments.

Library and Data Storage

- Networked and Local Databases: Globalized system for common tests, sessions, and results.

- Database Connectivity Toolkit: Enables regular pushing of test results to minimize data loss.

User Interfaces

- Three Tabbed Panels: Hardware, Test Sessions, and Analysis & Report.

- Hardware Panel: Access low-level commands for connected devices.

- Test Sessions Panel: Create, execute, and monitor test sessions.

- Analysis & Report Panel: Quickly generate reports in Word, Excel, and PDF using NI Report Generation Toolkit.

Conclusion

- Rapid Prototyping and Testing: LabVIEW environment with toolkits allows fast solution development.

- Testing Efficiency: 25% reduction in total testing time observed.

- Enhanced Test Sequence Implementation: Streamlined report generation.

- Multi-Device Testing Potential: Native multi-threading enables simultaneous device tests; eightfold throughput increase expected.