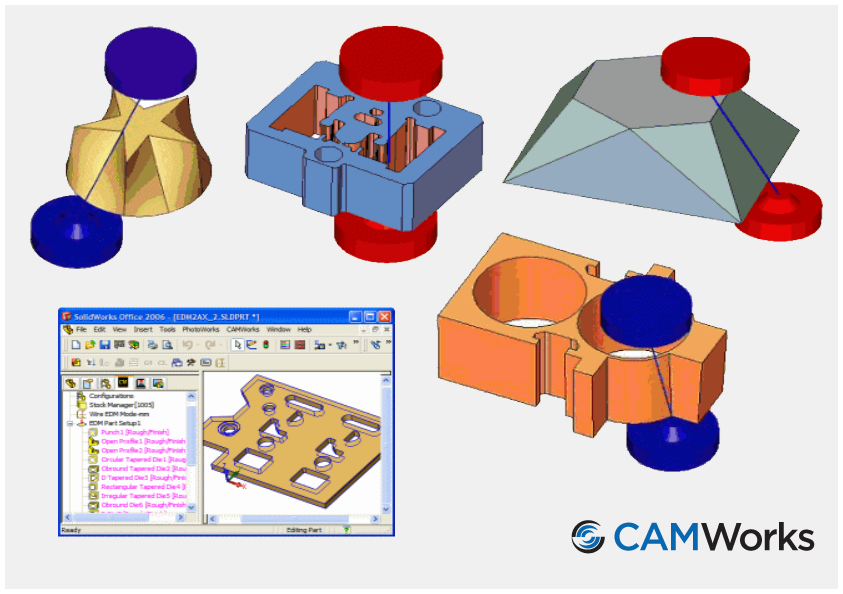

Wire EDM

CAMWorks Wire EDM software has been designed and developed specifically for programming 2 through 4-axis Wire EDM CNC Machines – unlike most CAM systems that use modified milling commands for their EDM programming modules.

- The 2.5 Axis and 4 Axis cutting operations automate the creation of rough, skim and tab cuts.

- Options are provided to order the cuts when machining parts with multiple pocket (die) areas.

- Numerous processing order options allow the user to automatically change the order with a single command.

- Ability to output only rough cuts, only tab cuts or both.

- Machine code output can be changed for a different machine by simply selecting a different machine make and model.

- Cutting conditions for the new machine are changed automatically as needed.

- Option for G-code to output offset toolpath.

Automatic and Interactive Feature Recognition

CAMWorks is a feature-based machining CAM system that provides the ability to automatically recognize Die (pocket) and Open Profile machinable features for Wire EDM.CAMWorks provides interactive 2.5 and 4 Axis Feature wizards to define features that are not recognized automatically or features that need to be defined for your particular machining requirements. Die (pocket), Punch (boss), Open Profile and Punch Perimeter features can be defined interactively.

2 and 4 Axis Contour Cycles

2 Axis Contour operations automatically generate rough, tab and skim cuts on 2.5 Axis features. Typically, this cycle would be used to cut a punch or die cavity. Optionally, CAMWorks can automatically generate toolpath passes that will cut both a die and punch at the same time. 4 Axis Contour operations automatically generate rough, tab and skim cuts on 4 Axis features.

Knowledge-Based Machining

Geometric Technologies’ proprietary TechDB, a Microsoft Access database, is the intelligence behind the machining automation in CAMWorks. Using Knowledge-Based Machining technology, the TechDB associates operation parameters to the machineable features. When you generate operations, CAMWorks applies these settings automatically.

Cutting Conditions Database

A cutting conditions database is associated to the post processor for the current machine make and model. The default data in the database is based on information from the machine tool manufacturer and optionally can be modified.